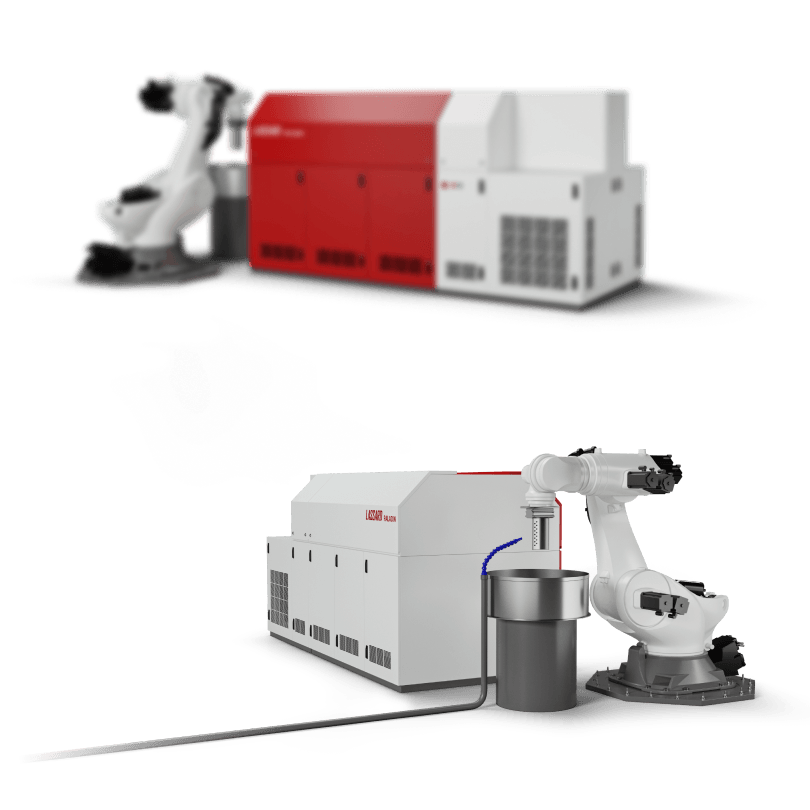

The PALADIN laser impact hardening complex can process titanium, nickel, aluminum alloys and steels.

- Guarantees high accuracy and controllability of the process

- Changes properties due to structural-phase transformations that do not require subsequent surface treatment

- Achieves a significant increase in strength and wear resistance of materials

- Depth of residual compressive stresses is up to 2 mm

- Increase in the magnitude of residual compressive stresses by 2–6 times

- Room temperature processing, due to which structural transformations do not occur in metals and alloys

- The complex is environmentally friendly, does not produce working gases

- Saving on energy costs due to the absence of isothermal exposures

The PALADIN laser impact hardening complex can process titanium, nickel, aluminum alloys and steels.

- Guarantees high accuracy and controllability of the process

- Changes properties due to structural-phase transformations that do not require subsequent surface treatment

- Achieves a significant increase in strength and wear resistance of materials

- Depth of residual compressive stresses is up to 2 mm

- Increase in the magnitude of residual compressive stresses by 2–6 times

- Room temperature processing, due to which structural transformations do not occur in metals and alloys

- The complex is environmentally friendly, does not produce working gases

- Saving on energy costs due to the absence of isothermal exposures