Reduce the time for processing engine blades 5-fold

Develop a stand-alone laser unit with three-dimensional cutting and simultaneous processing of several parts

Goals

The company was looking for a machine for manufacturing gas turbine engine blades, since standard flat cutting solutions were not suitable in this case because of the station three-dimensional shape of the blades. Moreover, the client wished to speed up the process of processing parts, so that the machine could process several blades in one go, rather than just one.

Solution

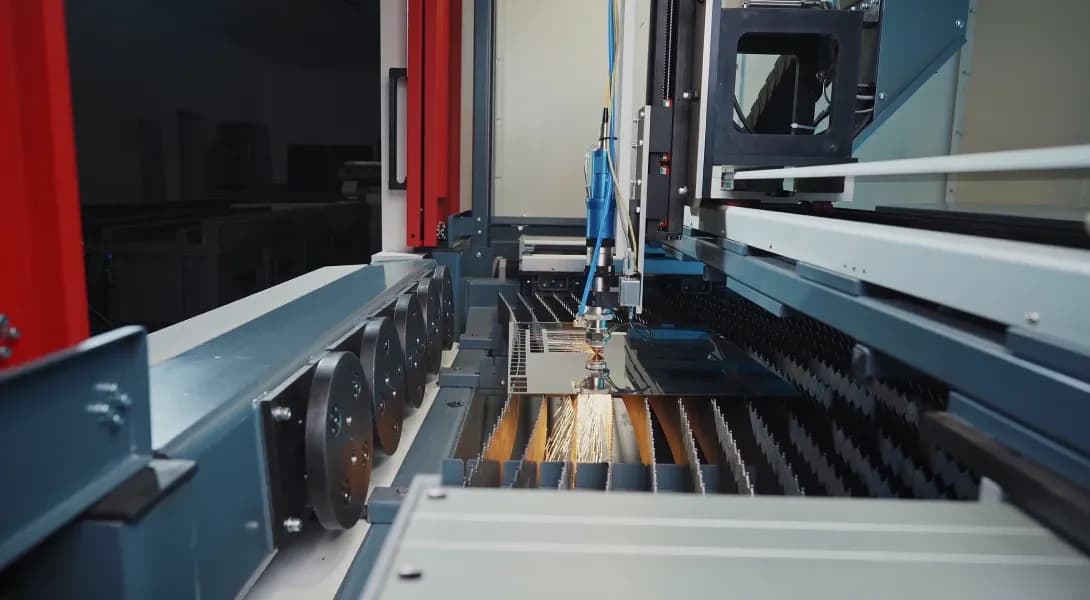

To develop such a non-standard machine, we took SMART BASE as a basis. In its basic configuration, it only performed flat cutting and could process one part in each cycle, which was not suitable for our client.

The task was completed quite quickly. For comparison: manufacturing a machine from a standard model range takes on average six months; our specialists completed non-standard equipment in eight months.

We made a 4D machine that processed five parts at once in one cycle; our specialists also assembled a two-dimensional cutting field with a rotating system, which opened up the possibility of processing blades in two planes. They named this station SMART TURN.

Result

The machine was delivered on time, and today it is already actively used at the UEC holding company Naro-Fominsk Machine-Building Plant. The client was satisfied.

After this order, our company included the SMART TURN 4D machine in the standard model range, and the station is in demand to this day.

Call or email us

On weekdays from 9 am to 6 pm. Our phone number is +7 495 120 68 86, you can also message us in the chat.

Visit the demonstration

In the showroom or online. You'll get to know all the details of working with laser technologies.